In terms of different types of pipes,the following will provide an introduction or explanation of related knowledge,specifically for the PE pipe.Moreover,it is an important product on the website and is related to the website keywords,so it is necessary to learn and understand it correctly and reasonably,so as to obtain good economic benefits instead of using it incorrectly.

1.Common welding methods for PE pipes

The commonly used welding method for PE pipes is butt welding.First,heat the end of the pipe,then use tools to make it contact and cool it under a certain pressure,thus achieving a good connection effect.Moreover,this method is very simple and easy to operate,so it is widely used.

Can PE pipes be used for sewage discharge?

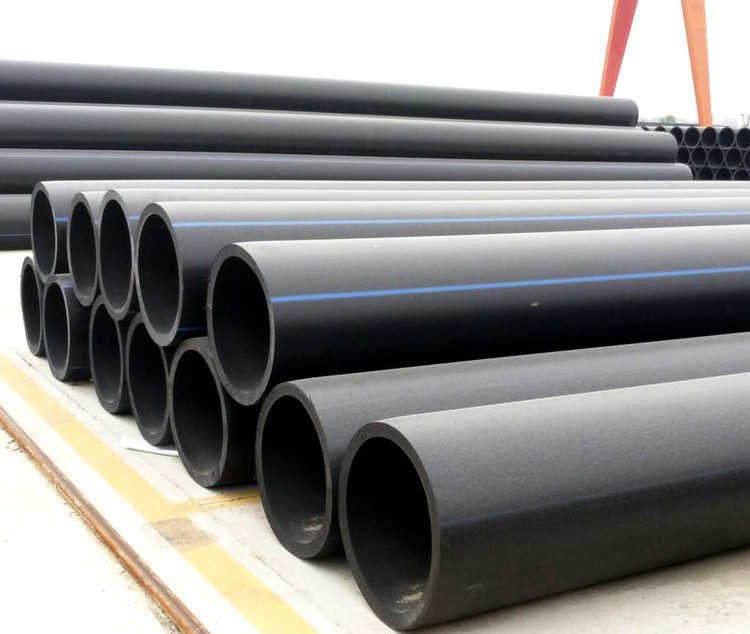

PE pipe,which can be used for sewage and can be referred to as sewage PE pipe,is a special pipe for sewage.High density polyethylene is used as the raw material,so it is called HDPE pipe and is a commonly used pipe material in municipal engineering and sewage treatment industries.Its characteristics are wear resistance,high temperature and high pressure resistance,and corrosion resistance,which can replace steel pipes for use.

3.Pressure rating and diameter size of PE pipe

The pressure levels of PE pipes mainly include 0.6MPa,0.8MPa,1MPa,1.25MPa,and 1.6MPa.There are many specific types of diameter sizes for PE pipes,so we won't give examples here.They are measured in millimeters.Moreover,the thickness of the pipe wall varies with different diameters.

Are the product standards and design standards for PE pipes the same?

It is obvious that the answer to this question is no,that is,the product standards and design standards of PE pipes are different.Because the former is a standard for product quality and other aspects,while the latter is a reference standard for product design.Moreover,the standard quantity is also different.So,we need to have a correct understanding of this and not make mistakes.