If the welding pressure does not meet the range that the PE pipe can withstand, it is very likely to rupture, and such a situation during use will also affect the normal use process. Therefore, before using the PE pipe, one should learn to calculate the welding pressure method.

PE pipes are often preferred by users, making them widely used in water and gas pipelines. Hot melt butt welding is a commonly used welding method for PE pipelines, and incorrect use of welding pressure can have a serious impact on the welding quality of the pipes.

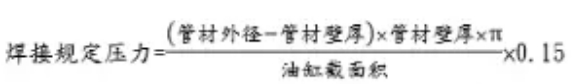

How to calculate welding pressure is an essential aspect to understand when using PE pipes for welding, due to their stable product performance, good toughness, and low temperature resistance. Welding pressure=drag pressure+welding specified pressure. What is drag pressure for PE pipes? Drag pressure refers to the displayed value on the pressure gauge when the oil cylinder of the welding machine frame drives the pipes and components to slide smoothly forward, which is the drag pressure value.

The testing method is to fully open the movable end of the welding machine frame, then release the pressure relief valve on the hydraulic control box, adjust the pressure regulating valve counterclockwise, and then place the direction control lever in the closed state. At the same time, close the pressure relief valve, visually inspect the position of the frame oil cylinder, and slowly increase the pressure regulating valve clockwise. When the frame oil cylinder drives the pipes and components to slide forward smoothly, the value displayed on the pressure gauge is the low drag pressure value.

Although PE pipes have better toughness compared to other products, it is still necessary for everyone to understand the pressure issue, and gaining more knowledge is also helpful for your use.